Call us 9:00am - 6:00pm

+86 18057013232

E-mail us

sales@kaishan-group.com

Monday to Friday

9:00am - 6:00pm

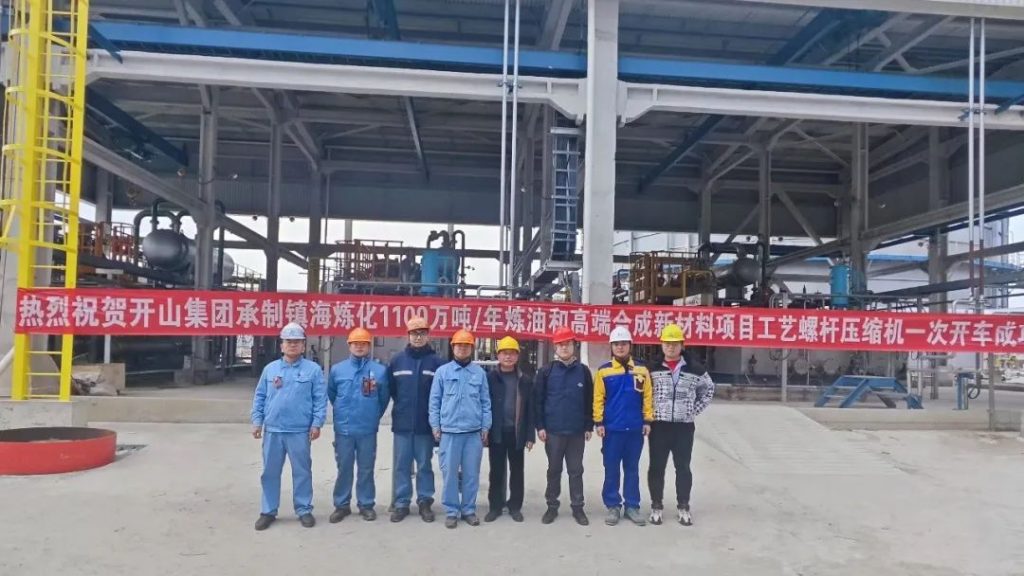

Kaishan News -The process screw compressor of Sinopec Zhenhai Refining and Chemical’s 11 million tons per year refining and high-end synthetic new materials project was successfully started up at one time

27th-Dec, good news came from the project site. The first process screw compressor of Sinopec Zhenhai Refining and Chemical’s 11 million tons/year refining and high-end synthetic new materials project undertaken by Kaishan Group Co., Ltd. was successfully started up at one time.

The Zhenhai Refining and Chemical’s 11 million tons/year refining and high-end synthetic new materials project uses three sets of Y-type line process screw compressors independently developed by Kaishan with complete intellectual property rights.

This project puts forward high requirements on the quality and energy efficiency of the process screw compressor. The project is time-sensitive and has heavy tasks. Among them, the K-203 unit with a single unit flow rate of 7000Nm³/h took only 175 days from the signing of the contract to the successful commissioning of the unit.

Kaishan adopts a fully skid-mounted modular design, with highly integrated units and easy on-site installation. The K-203 unit successfully completed the entire process from on-site installation to successful commissioning in just 40 days. The stable operation of the unit and the high efficiency of Kaishan have been recognized and praised by Zhenhai Refining and Chemical Company.

The petroleum refining field requires efficient and reliable process screw compressors to meet its special production needs. The successful commissioning of this unit indicates that Kaishan Group’s process screw compressors have reached the high standards of Sinopec’s leading enterprises. Kaishan Group provides more comprehensive solutions for customers in the field of petroleum refining with its leading ultra-large flow and high compression ratio process screw compression technology and rich project practice experience in the fields of oil, natural gas and chemical industry.